Successful

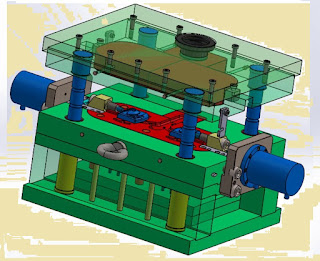

injection molding process design and simulation

Plastic injection molding is possibly the foremost widely used, yet least thoroughly understood manufacturing technologies in use today. Injection molding of thermoplastics began within the 1930s, long before the scientific study or understanding of the behavior of polymer melting struggling . it had been an empirical, trial by error industry, and therefore the critical element of low-cost, high-value part making—the mold—was designed by engineers who learned more by experience than from textbooks. it had been something of a sorcery .

Today, everything is different. the mixture of excellent

mathematical models of the rheology of resin melts, a far better understanding

of metallurgy and warmth transfer, and therefore the formalization of years of

“rules of thumb” has allowed specialist engineers to coach specifically in

plastic mold engineering.

injection moulding machine process

Iterative mold development, however, remains considerably

a tooling strategy. The difference today is that this is often done virtually

with simulation software. But why? Modelling of fluid flow in closed channels

has been finished decades. the rationale is within the resins, says Caitlin

Tschappat, Moldflow technical specialist with Autodesk and a specialist polymer

engineer.

“People don’t realize how complex plastics are and the

way they don’t behave like metals. They flow by non-Newtonian principles, with

very different flow properties. for instance , they’re highly shear sensitive.

It’s complex. many of us check out an easy part and think ‘oh, that’ll be easy

to fill.’ that straight forward shape might be one among the toughest parts to

manufacture due to many considerations, like warpage,” she explains.

At its simplest, injection molding is about orienting

cavities in three-dimensional space with a parting line that permits free

ejection of the cooled, solid resin parts. Simply determining the situation of

the parting line are often nontrivial. Parts with zero or negative draft angles

could also be impossible to eject with conventional ejector pins, forcing a

designer to use fewer cavities, or non optimal cavity orientation during a mold

to urge clean ejection. In some severe cases, there's no thanks to orient the

part to facilitate ejection, and core pulls must be used, adding complexity and

price .

injection molding machine working

The complexity doesn’t end there. Co-injection, over

molding—especially of TPU’s over commodity thermoplastics—and in-mold

decorating all complicate the mold design process.

If very high-volume production is important, like within

the packaging industry, stack molds may require complex designs with multiple

parting lines and a requirement for fast, clean ejection. Symmetry helps, and a

64 or 128-cavity small part mold could also be an easy matter of design

recursion. A family mold, however, or parts that need special features like the

favored “living hinge,” are often very difficult to style. There also are

multiple other issues involving gates, runners and other essential mold

features.

The advantages of simulation are obvious. Tschappat is an

industry veteran with experience within the packaging and automotive industries

and has seen this complexity up close.

“Think a few larger part,” she says. “The automotive

industry, for instance, has many long, thin parts. For these, you want to consider

the ratio with reference to part length to wall thickness, because it would be

difficult to fill uniformly without the inclusion of complex runner systems,

hot drops and valve gates. On the opposite hand, small parts, like those for

medical or electronic applications, can also require an equivalent complexity

with reference to the runner systems, as they can also be difficult to fill

thanks to small features and limited filling pressures.”

injection molding machine manufacturers

Modern mold design partially addresses the complexity

issue by the utilization of off-the-shelf mold bases, inserts, gates and other

standardized components wherever possible. Advanced simulation software like

Autodesk Moldflow works with these components to permit accurate approximations

of mold performance in gating and cavity filling.

Cavity balance is usually a high priority when filling

multi-cavity molds, which may sometimes be remedied through the utilization of

mold cavity symmetry. These instances also are ready to simplify mold

simulations, like how other Finite Element Analyses use symmetry for model

simplification.

For family molds, or large single cavity molds with

complex shapes, simulation makes the difference between a productive and

cost-effective tool, and a design that's revised such a lot it “goes through

the alphabet.”

Before simulation became more widespread, it had been not

uncommon to change important mold components on the fly, like quick-fixes to

gates for improving mold balance. Unfortunately, these are even as it

says—quick-fixes—leading to effects on other aspects like part quality like

jetting, knit lines and even dimensional instability. that sort of

experimentation may solve a drag , but it frequently requires a complete

rethink of the general molding strategy, with new machine parameters which will

require many shots to perfect.

plastic part design for injection molding an introduction pdf

The ability of simulation to attenuate rework not only

reduces time spent on the mold, but also the training curve on machine found

out with a replacement job. for outlets with a captive press operation, the savings

for reduced downtime and improved machine scheduling ability are obvious,

except for mold shops there are additional benefits. Rework costs and delivery

delays are reduced, customer satisfaction is improved, and therefore the too

frequent finger-pointing (who pays for that modification?) are often greatly

minimized.

Complexity may be a given with modern injection molding

and lots of jobs simply can’t be attempted without advanced simulation.

Tschappat describes how she uses Moldflow to deal with higher level problems,

saying, “We have many modules within the software counting on what questions

you would like answered, whether it's co-injection, two-shot, over-molding or

insert molding. for instance , with gas assist, we will help identify where the

gas void will settle within the cavity, or with coinjection how two plastics

are getting to bond together within the analysis.”

Simulation helps address the previously mentioned topic

of cavity balance for multi-cavity tools.

plastic part design for injection molding malloy pdf

"We see numerous tool cavity layouts when talking

with our simulation customers. But the one thing that always seems to throw

people off is that if they will escape with molding quality parts from family

tools, where each cavity could also be a special part, and technically would

wish different processing conditions,” says Tschappat.

“Using Moldflow simulation, we model up the mold layout

and predict the part quality of the various cavities. Then we experiment with

artificially balancing the filling through the utilization of adjusting runner

diameters between cavities or changing the runner design, to aim a more uniform

filling from cavity to cavity. albeit the filling is balanced, other factors

like shear-induced imbalances can occur as a results of the various geometry

features. this is often where simulation is basically cool—seeing something

that we will not even see with our eyes when actually molding the parts at the

press," she adds.

The types of runners are another source of complexity.

Hot runners are standard for volume production thanks to zero or minimal wasted

material, but cold runners leave re-purpose of their runner material toward

regrind to feature to material savings through reusing small percentages. But

as Tschappat observes, “based on your part, what's the simplest gating scheme?

counting on how big your part is, maybe you're employing a fan gate, or if it

is a smaller part it'd be alittle pin gate. Then the pressures and therefore

the pressure drops are an element throughout the runner system. These are all

things that make it complex, yet you've got to weigh them out at the top of the

day to work out what's best for your business.”

Even a seemingly simple change during a commodity resin

can introduce issues. “They teach you in class that if you're getting to be

employing a different resin, particularly very dissimilar materials to people

who you’re wont to , you ought to build your mold thereto material,” Tschappat

says. “We all know that that's not necessarily the practice. you'll start out

with a non-filled material then plan to switch to a glass-filled material after

manufacturing a couple of shots, for instance . Now you've got to stress about

more abrasive decline the tool over time. What does one neutralize those

situations? More frequent tool inspections and reworks, maybe even welding up

the gate and re-cutting it so it allows for fewer shear of the fibrous

material. These kinds of things just take overtime out of the method and slow

you down, but it's normal practice.”

injection molding machine design simulation pdf

The ability to rerun a simulation with a replacement

material virtually can flag a molder about potential problems before they

translate to expensive tool rework and downtime. Warpage is another common

reason for modifications to the tool design. an honest designer who has

familiarity with simulation packages like Moldflow can gain insight into root

causes of those problems.

“Once you actually get comfortable, you'll actually

isolate causes of the warpage to raised understand why something is warping,”

states Tschappat. “For example, if you're getting tons of warpage thanks to a

thicker cross-section because your material's not freezing off and you've got

tons of shrinkage therein area, Moldflow allows you to ascertain that then make

a design change and rerun an analysis to see how that style change reduces

overall warpage. this is often why we are working more and more with part

designers. they will use simulation as they design the part to flag these

problem areas before escalating to the tool designer, resulting in fewer

iterating between the 2 , making them appear as if they're superstars!”

injection moulding machine training

The cooling issue is critical and is usually harder to

perfect than the cavity and runner design. Although 3D printing promises truly

conformal cooling, most production molds are cooled by drilled and manifolded

channels carrying coolant, usually water or oil, which carries the warmth away

by the thermalator.

There’s an old rule of thumb that for efficient cooling,

set the machine to eject the part at 80 percent of the part’s heat distortion

temperature. However, for complex parts, multiple cavities or complexity added

by factors like thermoplastic elastomers, coinjection or gas assist, rules of

thumb are quickly replaced with empirically derived settings during the mold

runoff. Cooling is typically the determining think about overall cycle time, so

here time considerably is money.

Simulation of cooling channel layout and flow capability

are often equally or more important than efficient cavity filling for a high

capacity mold, and within the world of injection molding, only a few molds

aren't thought of as high capacity, meaning cooling is nearly always a critical

factor.

Mold designers are frequently faced with customer

requirements which will be difficult or maybe impossible to realize . Most

production shops understand their press plate size and tonnage, chiller capacity

and target cycle time, but know little about the mold.

Customer expectations can sometimes be unrealistic. “Part

designers and mold engineers need to work with each other ,” says Tschappat.

“Time is money, and everything must be finished yesterday. It goes through

several phases. How are you getting to lay your model out? you've got to think

about where you are going to inject resin and locate your gates. then what sort

of gate you are going to use. What sort of runner systems? Is it getting to be

a hot manifold or are cold runners getting to be sufficient? Or is it a hot to

cold runner? what is the ejection unit look like? Where are you able to squeeze

cooling in?”

injection molding operator training

“Often in my job, you get parts from customers and you

ask them, ‘what's your cooling layout look like?’ you'll get a solution thereto

question, or they'll not know. Often a designer will just squeeze cooling in

there wherever they need extra room left over,” Tschappat adds.

Even the potential of the machines that run the mold are

often assessed critically with mold simulation. Simulation allows a mold

designer to run “what if” scenarios which will show a customer where

expectations are unrealistic and nudge them to a far better mold design without

an argument.

Math is definitive. “If you're limited within the types

or how large your injection molding machines are, then you're limited to the

dimensions of the mold that you simply can put therein unit,” Tschappat says.

“And then in fact , what proportion pressure it's getting to fancy fill these

parts? is that the machine large enough to not just fill out the cavities, but

hold the pressures needed to pack those parts? If it isn't , you are going to

possess some problems and you're either getting to need to redesign the tool or

reconsider it. Or buy a replacement machine.”

This isn’t a theoretical consideration. Tschappat has

seen customers who were spared the value of a replacement machine when shown

the advantages of a far better optimized mold design.

learn injection molding

Does simulation replace the tooling designer?

“No,” declares Tschappat. “I would say there's still an

art thereto. When I'm in conversation, I regularly tell people they ought to be

using simulation as an additional datum or another datum , and use their

experience. This actually ties into that aging workforce, too, as we're

beginning to lose that skillset. People are retiring, so how can we build that

have base up? Simulation may be a specialized thanks to help. children got to

be sponges; if you are a toolmaker or a tool designer, work closely with the

older generation to select up a number of their skills.”

Simulation software for injection mold design has

progressed from “nice to have” to a “must have” for cost effective tooling

“I think it did wonders for the industry because you are

able to create an ROI case and see where you'll improve cost savings at the top

of the day. Everybody wants a more complex part cheaper, faster, quicker, and

by incorporating this type of technology into your workflows and work

processes, we will help achieve that goal for our customers.”